Corporate profile

Medium-sized – successful – innovative

The headquarters of the SIMON GROUP is located in Aichhalden near Schramberg. In total our group of companies employs around 740 people. The SIMON GROUP unites the three companies BETEK, SITEK and SIMON Sinterlutions, as well as the business divisions SIMON Tooling and SIMON Analytics under its umbrella. As a global player, the group of companies now stands for over 40 years of expertise in the processing and machining of carbide.

The individual companies have been subsidiaries of the listed INDUS-Holding AG since 1992. They act both independently and jointly on the market. In addition to the main plant in Aichhalden, Betek also operates a production site in Taicang, China and a sales office in the USA.

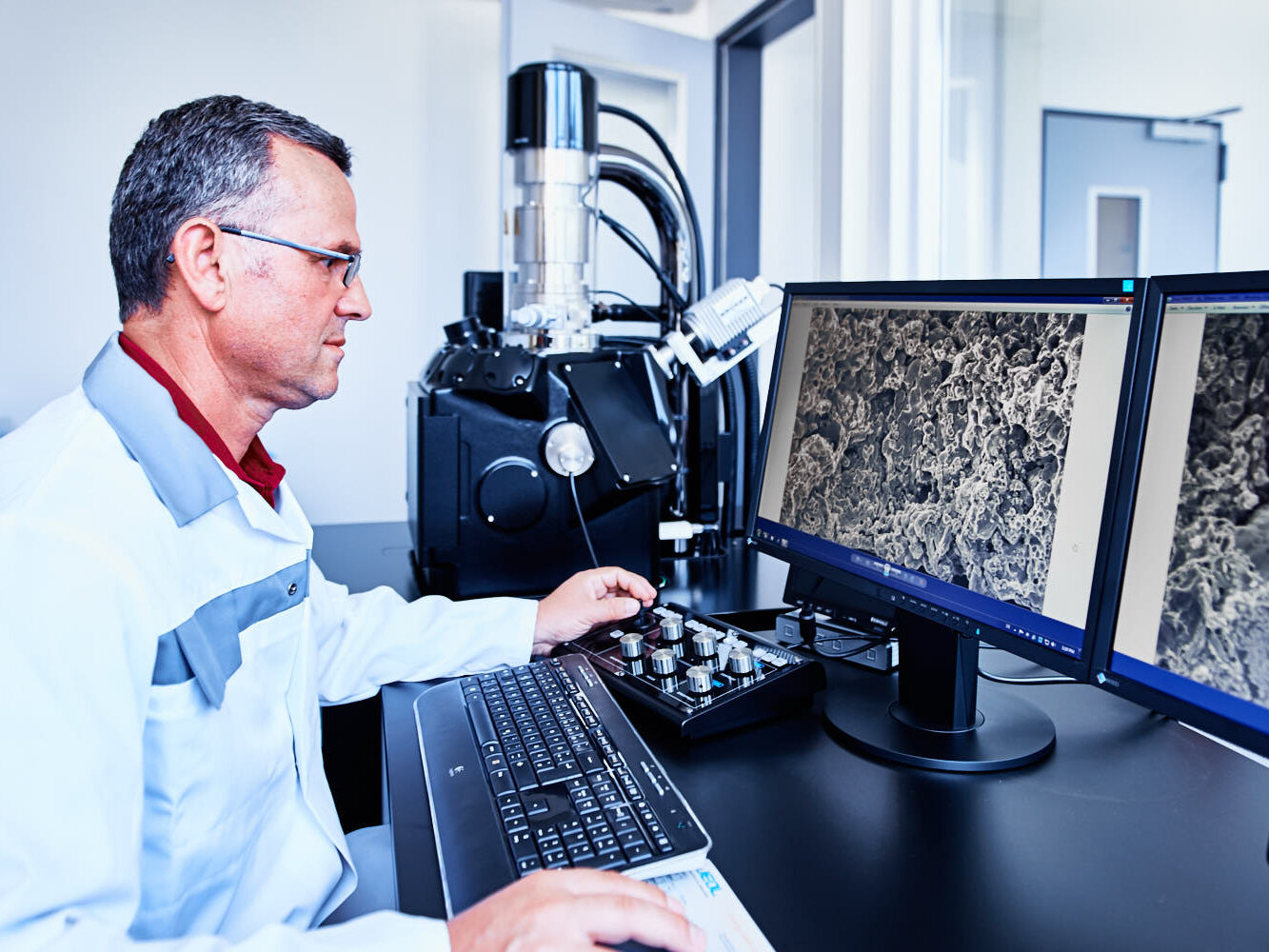

In each and every one of our companies, we pay close attention to ensuring flat hierarchies and flexible processes. These are regularly reviewed and improved. Our employees manufacture a comprehensive range of products and services at the highest level of quality. Important cornerstones for the continuous quality of our work are the central services of the company group. These include administration, purchasing, quality management, electrical workshop and maintenance, as well as the company’s own materials laboratory and toolmaking shop.