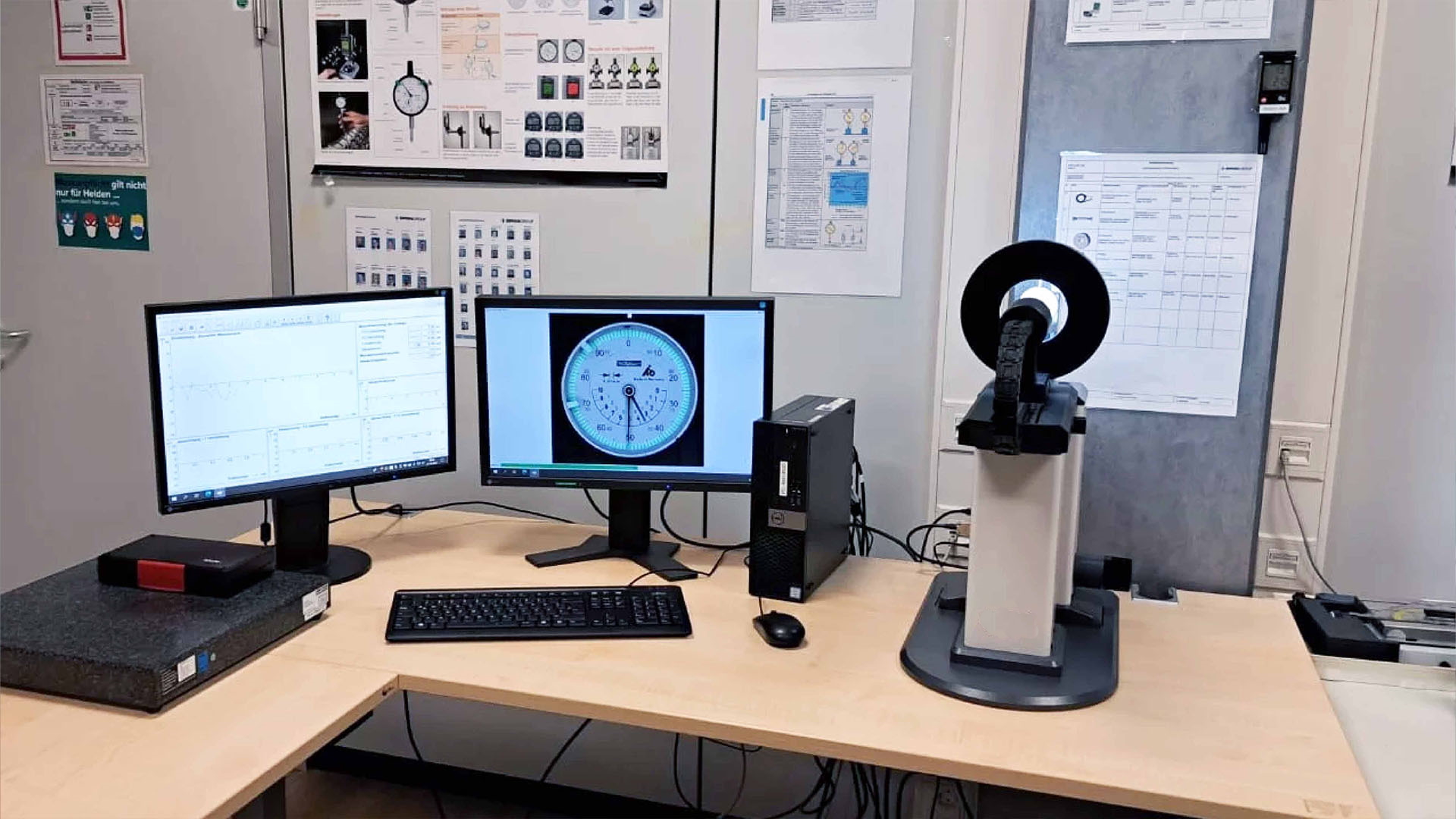

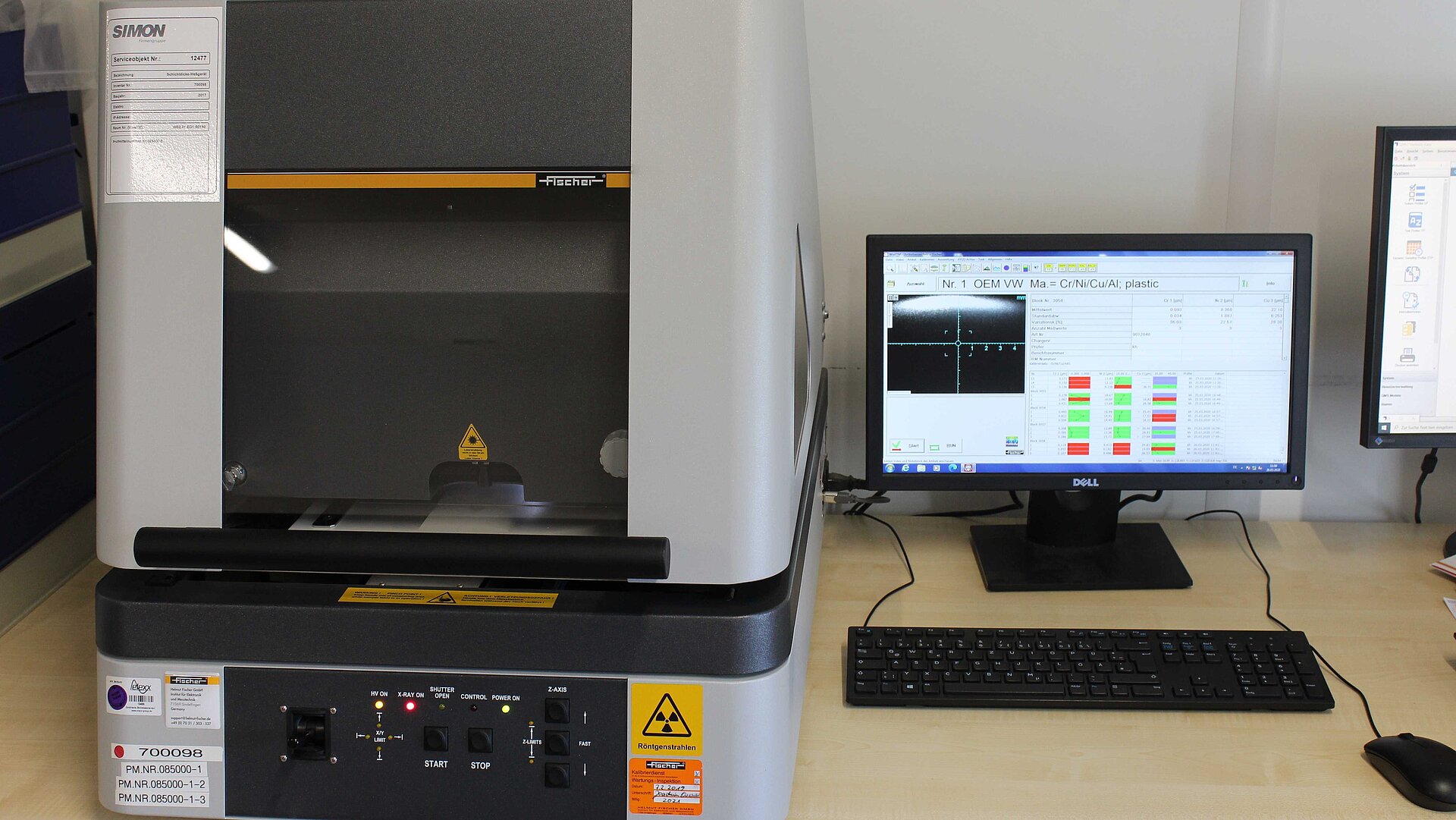

Welcome to SIMON Analytics Founded in 2020 Support in the areas of metrology, process analysis, test equipment management and calibration. Rework and assembly activities Equipped with modern testing equipment. Support in the implementation of new test methods in the areas of corrosion, climatic, physical-technical, coating thickness and resistance tests on coated materials.

SIMON Analytics is the in-house testing laboratory of the SIMON GROUP. Here, we can perform corrosion tests, climate tests and coating thickness measurement for the carbide tools, tool systems and wear protection solutions we have developed. We are happy to offer these and other special tests to customers on request.